Recycled

We reduce CO2 emissions by incorporating recycled materials into our products

Recycled

The standard UNE-EN 15343 defines recycled content as “the proportion, by mass, of recycled material in a product or packaging”.

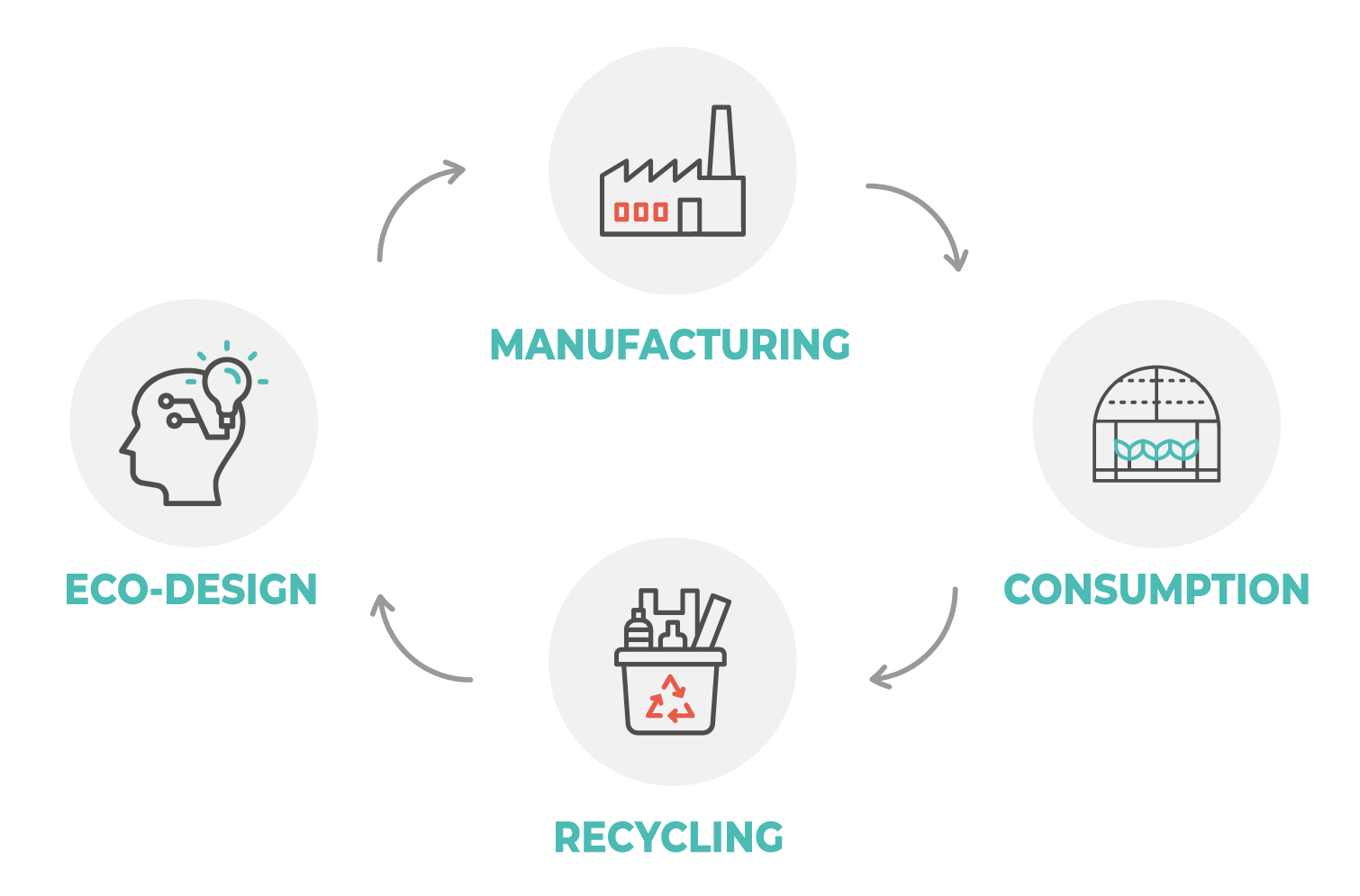

Our goal is to prevent plastic waste from ending up in landfills or abandoned in places where it doesn’t belong. By recycling, we refer to plastic waste that returns to the value chain after a transformation process, making the circularity of plastics possible. For this reason,we are committed to its reincorporation into our production process.

Mechanical or chemical

recycling

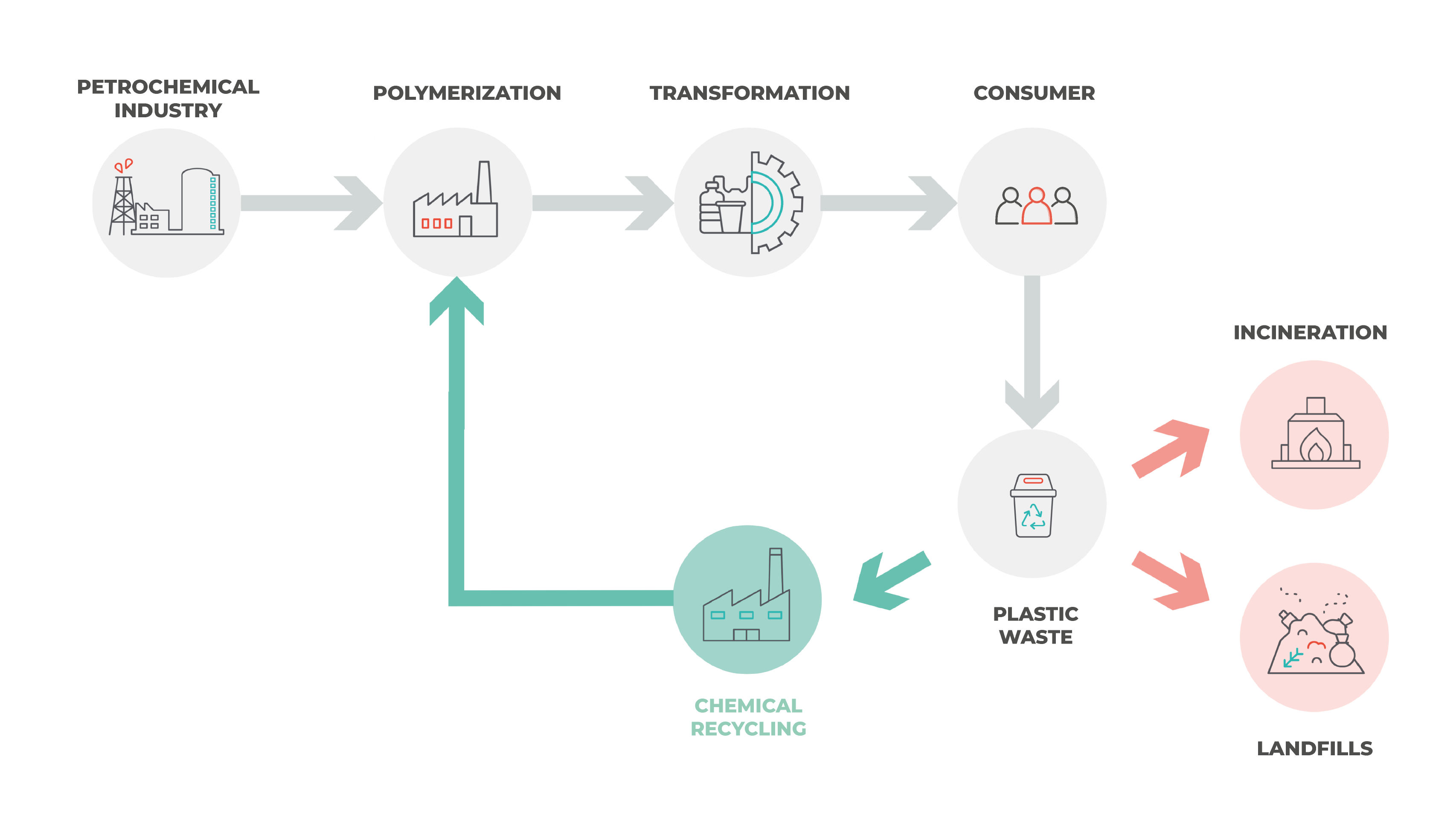

The transformation of plastic waste can be carried out through a mechanical or chemical process. These processes complement each other since chemical recycling is complementary to mechanical recycling since it enables us to use plastic waste that mechanical process cannot.

Mechanical

Recycling

It is an alternative with a more economical process and with greater savings in CO₂ emissions that enables recycling with good performance depending on the quality of the waste. This process involves prior separation and cleaning, and the resulting products are not suitable for food contact.

What products do we use in mechanical recycling?

Pre-consumer material

Recovered from the waste stream during a manufacturing process before being consumed.

Post-consumer material

Generated by end-users for domestic use or by commercial, industrial, and institutional facilities.

Chemical

Recycling

Chemical recycling complements mechanical recycling by treating the portion of plastic waste that the mechanical process cannot.

In chemical recycling, polymer molecules are broken down into raw materials (monomers). This process allows petrochemical companies to manufacture new plastics through new polymerization processes, among other things.

The most widely used chemical recycling technique is Pyrolysis, which is thermal depolymerization using heat and without chemical reagents.

Chemical recycling advantages

- Food contact

- Homogeneity

- Complementary to mechanical recycling

- Same technical performance as virgin raw material

- It doesn’t require the previous separation of waste

ECOsolutions

Recycling

Designed to give a new life to plastics

Solutions for collation-shrink

We offer different solutions concerning the recycling percentages included in the formulation without sacrificing mechanical properties.

Solutions for Recovered Mulch films

This mulch film is made from post-consumer agricultural material. Technically designed to maintain its performance during field installation.

Packaging Rope Solutions

For its development, we use high-quality recycled materials to achieve a material with high performance that’s also environmentally friendly.

Twine solutions for tutoring

Blow-molded packaging solutions

Silage Solutions

Made from highly refined recycled polymers, achieving technical properties equivalent to those of premium films.

If you are looking for more solutions with recycled materials

other

ecosolutions

BIO

OPTIMA

360º

ESSENTIAL

Sustainability plan

Ecoinitiatives

Transparency

GoCircularPlastics

We promote plastics circularity